It Is suitable for packaging with Paper card and Plastic blister in the industrial of stationery, small hardware, medical equipment, toys, battery, electronic products, automobile and motorcycle fittings, commodity, cosmetic, rubber products, dinnerware, and kitchenware. For example, the medicine injection,syringe, toy car, flashlight, spark plugs, toothbrush, lipstick, facial mask, chopstick, shaver, scissors, hooks, cleaning balls, bottle openers, correction fluid,ball pen/pencil, sharpener, etc.

Online InquiryBHB-350B Turntable Type Semi-automatic Paper Plastic Packaging Machine

Main Technical Parameters

|

Production Frequency |

10-25 times/min |

|

Maximum heat sealing area |

350 x 200mm |

|

Sealing and Heating Power |

3.5KW |

|

Total Power |

380V 50HZ(480V 50HZ)6KW |

|

Air Pump Volume Flow |

≥0.6m3/min |

|

Packing Materials |

Paperboard ≤350×200×O.5mm (LxWxH) |

|

Overall Dimensions |

2200×2500×l820mm (LxWxH) |

|

Weight |

800Kg |

It Is suitable for

packaging with Paper card and Plastic blister in the industrial of stationery,

small hardware, medical equipment, toys, battery, electronic products,

automobile and motorcycle fittings, commodity, cosmetic, rubber products,

dinnerware, and kitchenware. For example, the medicine injection,syringe, toy

car, flashlight, spark plugs, toothbrush, lipstick, facial mask, chopstick,

shaver, scissors, hooks, cleaning balls, bottle openers, correction fluid,ball

pen/pencil, sharpener, etc.

It is especially suitable for the company who has various types of products,

and the production capacity is not high, needs to change the molds frequently.

Main Performance

Characteristics

This is a rotary heat

sealing machine independent, with automatic suction blister

(optional),decentralization of products (optional), suction card, automatic

sealing, finished feeding and other functions;No foam shell molding, no punching device, so that the replacement of the mold

more convenient and efficient, and more cost savings;Fully automatic, can help save labor;Low noise, high quality;

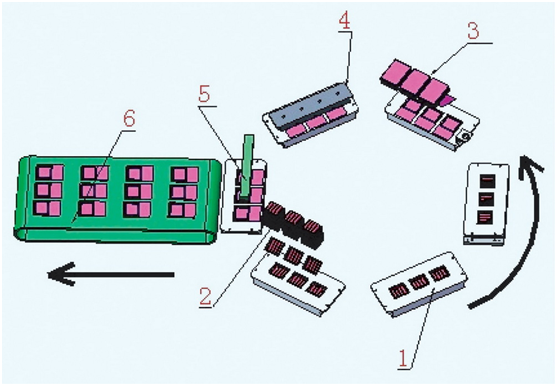

Schematic diagram

1、Product display area 2、Blister placement 3、Paperboard Placing 4、Heat Sealing 5、Output 6、Finished product transportation