1.Auto cuttingknife system, new structure of cutting cylinder. Easier to adjust air cylinder travel when changing different diameter mould.

2. 3 sets servo motor for cutting system moving left & right, supporting roller and cutting knifes.

3. Automatic paper roll connecting function bracket.

4. Glue heating and recycle function glue station.

5. Main electric parts choose famous brand, Schneider. Like main servo motor, servo motor driver, frequency charger.

BH-50High-speed CNC Paper Straw Machine

Technical

Parameters:

|

Paper Layer |

3 layers |

|

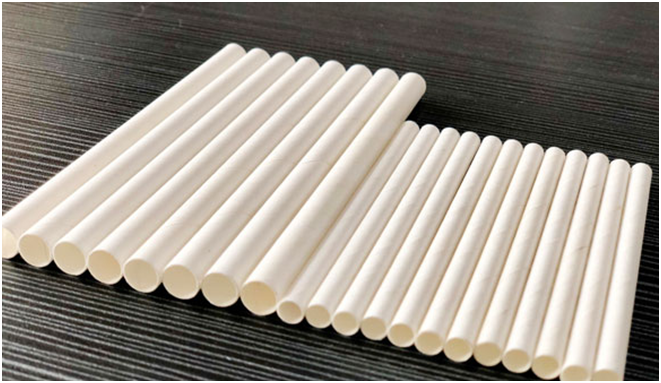

Inner Diameter |

4.5-12mm |

|

Wall Thickness |

0.3-1mm |

|

Stable Speed |

30-40 meters/min |

|

Cutting System |

Multi-blades Cutting (5 pcs online) |

|

cutting system |

Servo motor synchronism tracking cut |

|

Gluing Way |

Single & Double sides |

|

Machine & Parts |

Stainless Steel or Painting (Optional) |

|

Auto Straw Collector |

Optional |

|

Operator |

1-2 person |

|

Speed Control |

By Inverter |

|

Power Supply |

380V / 3Phase / 50Hz |

|

Paper Reel Stand |

3 Layers |

|

Glue Unit |

3 Layers |

|

Belt |

5 Pieces |

|

Mandrel Shaft |

2 Pieces |

|

Measurement |

3500*1500*1200mm |

|

Weight |

1300kgs |

|

Working Space |

About 8000*5000mm |

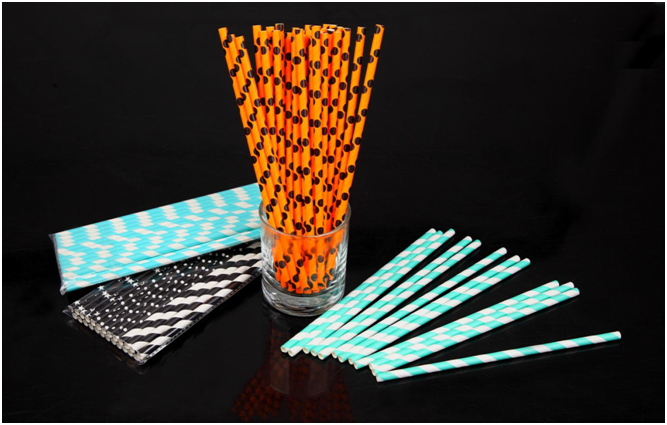

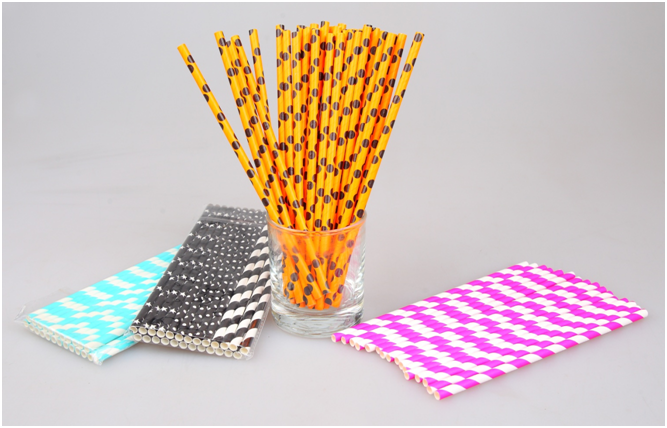

Escriptions: This Machine is suitable for

producing different sizes of paper straws, such as 5mm; 6mm; 8mm; 10mm etc.

1. Adopted with PLC controller; main motor is equipped with variable frequency

speed regulation; touch screen man-machine interface. Easy for parameters

setting & operating.

2. Cutting section adopted with numerical multi-blades cutting system. Servo synchronous

tracking cutting system makes it higher precision and multi-blades cutting

makes it higher efficiency.

3. Machine body and main spare parts made by stainless steel instead of

painting. Ensure the hygiene and environmental protection of the products.