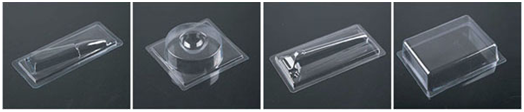

The equipment is suitable for forming plastic trays, for purposes of blister packaging of many industrials, like stationery, small hardware, medical equipment,toys, battery, electronic products, automobile and motorcycle fittings, commodity, cosmetic, rubber products, dinnerware, kitchenware, and so on. For example, the medicine injection, syringe, toy car, flashlight, spark plugs, toothbrush, lipstick, facial mask, chopstick, shaver, scissors, hooks, cleaning balls,bottle openers, correction fluid, ball pen/pencil, sharpener, etc.

Online InquiryBHP-500B Tray Forming Machine

Main Technical Parameters

|

Items |

BHP-500B |

BHP-350B |

|

Max. Cutting Speed |

Plastic 15-35 times/min |

Plastic 15-35 times/min |

|

Adjustable Travel range |

35-160mm |

35-160mm |

|

Max. Forming Area |

480 × 160mm |

350 × 160mm |

|

Max. Forming Depth |

40mm (Special 50mm ) |

40mm (Special 50mm ) |

|

Forming Heating Power |

5KW |

3.6KW |

|

Total Power |

380V 50HZ (220V 60HZ) 7KW |

380V 50HZ (220V 60HZ) 5.5KW |

|

Main Motor Power |

2.2KW |

1.5KW |

|

Air flow |

≥0.4m3/min |

≥0.25m3/min |

|

Dimensions |

2500×l000×l700mm (LxWxH) |

2500×900×l600mm (LxWxH) |

|

Weight |

1300Kg |

950Kg |

The equipment is suitable for forming plastic trays, for purposes of blister packaging of many industrials, like stationery, small hardware, medical equipment,toys, battery, electronic products, automobile and motorcycle fittings, commodity, cosmetic, rubber products, dinnerware, kitchenware, and so on. For example, the medicine injection, syringe, toy car, flashlight, spark plugs, toothbrush, lipstick, facial mask, chopstick, shaver, scissors, hooks, cleaning balls,bottle openers, correction fluid, ball pen/pencil, sharpener, etc.

Main Performance Characteristics

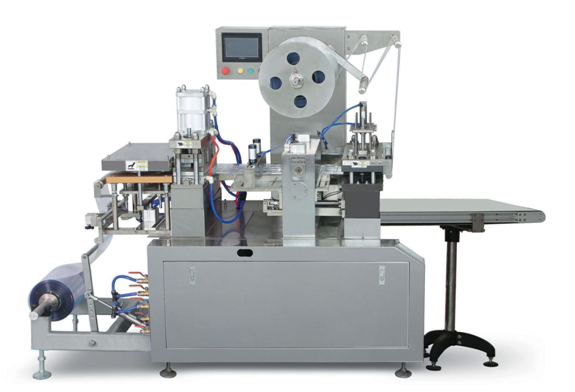

Positive/negative pressure Molding, simple structure, convenient operation.

304 stainless steel shell, conforms to the national pharmaceutical industry GMP requirements,beautiful appearance, easy to clean.

Adopt imported frequency control, color touch screen (man-machine interface) and PLC programmable control system, high yield, low noise, clear and simple operation, more advanced automation, more humane.

Adopt servo motor stepless stroke control, stroke adjustment is simple, easy to changeover the molds.

Photoelectric control, full automatic.

Compact structure easy to transport and lift access.

The respective plastic material feeding device, can save a lot of packing material, scrap edge can be collected.

Molds designed according to requirements and automatic overlapping equipment is optional.

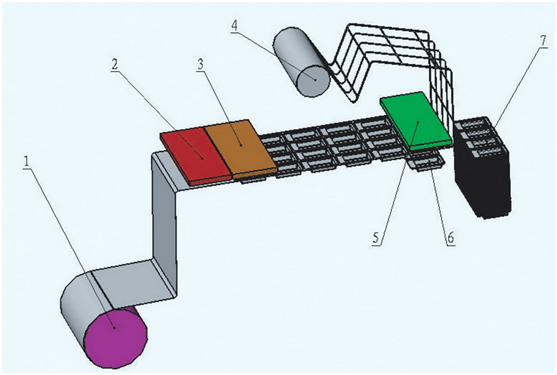

Schematic

diagram

1、Plastic Material Releasing 2、Pre-heating 3、Forming 4、Material Scrap Edge Collecting 5、Cutting 6、Stripper 7、Output(Automatic Overlapping is Optional)